Understanding the Role of Pigging System Applications in Modern Pipelines

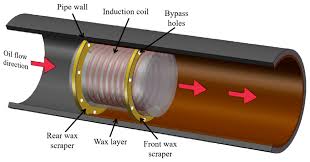

In industries that rely on pipeline systems for transportation, whether it’s for oil, gas, chemicals, or even food products, ensuring that the pipeline remains clean, safe, and operational is essential. One of the most efficient ways to achieve this is through the use of a pigging system. Pigging systems are indispensable tools used in pipeline maintenance to perform a variety of tasks, such as cleaning, inspection, and even separation of different products. This article explores the various pigging system applications, the benefits they offer, and their importance in maintaining pipeline integrity.What is a Pigging System?A pigging system is a network of components designed to send mechanical devices, known as pigs, through a pipeline to perform specific tasks. These pigs are typically cylindrical and are made from materials such as steel, polyurethane, or rubber. They are inserted at one end of the pipeline and moved along the pipe using the flow of the substance being transported or through mechanical propulsion. The pigs come in various forms, each designed for a specific pigging application. The most common uses for pigging systems are cleaning, inspection, and maintaining the integrity of the pipeline.Key Pigging System Applications1. Pipeline CleaningOne of the most common pigging system applications is cleaning the interior of pipelines. Over time, pipelines can accumulate various forms of debris, such as scale, sludge, wax, and other contaminants. If left untreated, these build-ups can reduce the efficiency of the pipeline, cause blockages, or increase operational costs. Cleaning pigs are used to remove these buildups by scraping or scrubbing the inside walls of the pipeline. Some pigs are fitted with brushes or scrapers to ensure that every inch of the pipeline is cleaned effectively.This cleaning process helps restore the pipeline’s original flow capacity, allowing the transported materials to flow smoothly without obstruction. Regular cleaning also prolongs the life of the pipeline, reducing the likelihood of breakdowns and unexpected shutdowns.2. Pipeline InspectionAnother essential pigging system application is pipeline inspection. Over time, pipelines are subjected to wear and tear, and it’s crucial to regularly inspect them for signs of damage, corrosion, or cracks. Smart pigs, which are equipped with advanced sensors, are used in this application to scan the pipeline’s internal structure. These pigs are designed to detect anomalies such as corrosion, dents, cracks, and other signs of damage that could compromise the safety and efficiency of the pipeline.Smart pigs use a combination of ultrasonic testing, magnetic flux leakage, and other non-destructive testing methods to gather real-time data about the pipeline’s condition. This information is crucial for identifying problems early, allowing operators to address issues before they lead to costly repairs or, worse, catastrophic failures.3. Product SeparationIn many industries, pipelines transport a variety of different products, and it is essential to keep these products separate to avoid contamination. Pigging system applications play a vital role in this regard by allowing for product separation within the pipeline. For example, in the oil and gas industry, different types of crude oil or refined products are often transported in the same pipeline. By using pigs to create physical barriers between the different products, operators can ensure that the products do not mix, maintaining their integrity.Product separation pigs are specifically designed to handle this task. These pigs are equipped with sealing elements, such as rubber cups, which help separate one product from another as they move through the pipeline. This prevents cross-contamination and ensures that each product remains as pure as possible, which is particularly important for industries that deal with high-value products.4. De-watering and Fluid RemovalAnother significant pigging system applications is the removal of unwanted liquids, such as water, from pipelines. Water accumulation is a common issue, especially in pipelines that transport oil and gas. Water can lead to corrosion, which can damage the pipeline and reduce its lifespan. Additionally, the presence of water can contaminate the product being transported, affecting its quality.De-watering pigs are designed to push unwanted fluids through the pipeline, leaving only the desired product behind. These pigs are typically fitted with rubber or foam cups that form a seal against the pipeline wall, enabling them to push water or other liquids ahead of them as they travel through the system. By removing excess liquids, de-watering pigs help prevent corrosion and ensure that the transported product remains free of contaminants.5. Flow AssuranceFlow assurance is a critical task in maintaining the efficiency of a pipeline. Over time, substances such as wax, paraffin, or hydrates can build up in pipelines, which can lead to blockages or reduced flow. This issue is especially common in colder regions where waxy substances solidify more easily. Pigging system applications are used to ensure that these substances are removed before they cause any operational issues.Flow assurance pigs are specially designed to address these problems. These pigs can help break up wax or hydrate formations, keeping the pipeline flow uninterrupted. By using pigging systems for flow assurance, operators can avoid costly downtime and ensure that their pipelines operate at peak efficiency, even in harsh conditions.ConclusionThe various pigging system applications are critical to ensuring the safe, efficient, and cost-effective operation of pipeline systems. Whether it’s for cleaning, inspection, product separation, de-watering, flow assurance, or general maintenance, pigging systems play a crucial role in enhancing pipeline performance. By preventing costly repairs, improving safety, and optimizing operational efficiency, pigging systems provide significant value to industries that rely on pipeline transportation, ensuring that these vital systems operate smoothly for years to come.