The Factors On Which Superior Quality Tools And Tool Making Industry Are Dependent

Tool making is an important process that entails engineering and designing tools to the perfection required in the manufacturing of various other components and parts for various industries. After it is crafted, then extensive testing is carried out to ensure that it is a perfect piece that will enable smooth production processes.

Why Is It Important To Make Tools?

Tools are required in everyday lives. Tool making is essentially required for manufacturing high-quality finished parts or various other products. It facilitates the production of a certain item very precisely and there are various tools used for a single project. Advanced tools can help you to complete your project faster and you can increase your productivity by using such tools. Even the volume of production with the aid of the tool is very important in judging its effectiveness. Thus, it is very important that tools are designed and manufactured accurately.

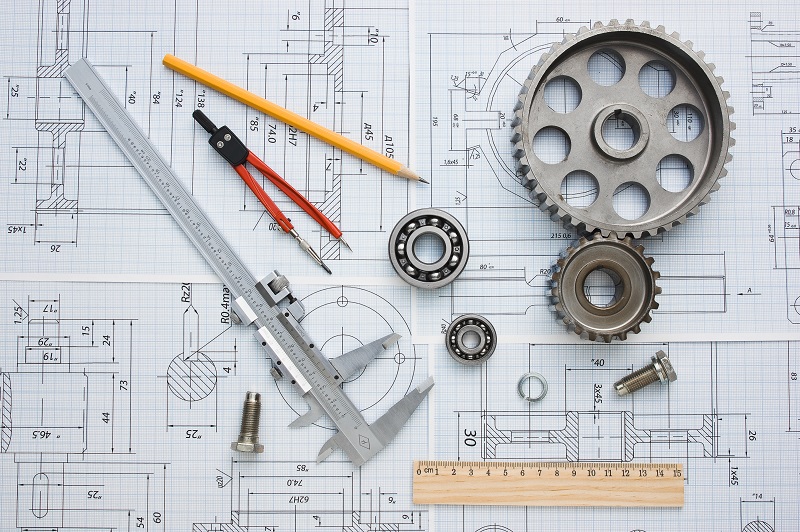

Common Tools That Are A Result Of The Tool Making Process

Tool making comprises one of the most important jobs because that in turn facilitates smoother and faster production of other items that are manufactured in various industries. The common tools that are an important part of the tool-making industry are metal forming rolls, lathe bits, form tools, and milling cutters. Sometimes this process requires the items to be custom-made so that they can perfectly fit into the user’s requirement process.

Components Of The Tool Making Process

Tool making is part of the original design of the new machine and tools to aid production and newer designs. It is inclusive of the original blueprint right to the procedure of testing the tool in question. It also includes assembling the products to make one cohesive whole that will allow superior production with its usage. If you consider small tools that are used to make one whole machine then the tool maker must have thorough and comprehensive knowledge about such tools and techniques. Each tool comes with a manual and people can use this manual to learn the process.

The Basic Raw Materials That Are Used In The Tool Making Industry

Tools are in general made from metal and very specifically if you pinpoint the metal then it is invariably made from highly durable steel. The tool making industry also uses certain alloys like chromium and vanadium. They are used because they are abrasion-resistant which makes the tools very durable and long-lasting.

Of the alloys mentioned above, vanadium is a very frequently used material for tool making because it makes the tool very hard in nature. Chromium allows the item to get prevented from deforming which can easily take place while the manufacturing process is on. It also helps to prevent the steel from breaking apart.

The Procedure For Manufacturing The Steel For Tools

The raw materials that are used by the tool making industry are very important. This decides whether the tool will be good or bad. It also reflects on many factors like its longevity and effectiveness. So the best materials should always be used. The steel that is best for the tools is made by electric furnace melting, electro slag refining, primary breakdown, rolling, hot and cold drawing, and continuous casting.

When you make use of the best raw materials that are crafted by the finest of technicians then you can expect the best tools that the tool making can ever produce. So these are two factors on which the quality of the tools is dependent, – materials and usability. You need to use the right materials based on the purposes of such tools.