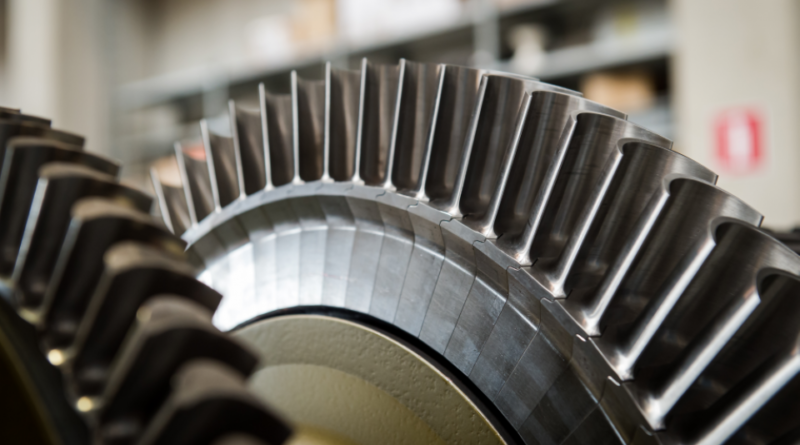

Steam Turbine Blades Repair – A Comprehensive Guide

Steam turbines are used in many industries including power generation, oil and gas plants and ship propulsion. Steam turbines are complex pieces of machinery and require regular maintenance and repair to ensure they are operating at their best. One of the most important components of a steam turbine is the blades. Repairing or replacing turbine blades is a difficult process that requires specialized tools and knowledge.

Inspection and Diagnosis

The first step in repairing steam turbine blades is to inspect and diagnose the problem. The blades must be inspected for any damage such as cracks, missing pieces, or warping. It is important to identify the cause of the problem, as this will determine the best course of action for repair. Professionals may use ultrasonic testing to determine the exact nature of the damage and the best repair procedure.

Replacement Parts

Once the damage or wear has been identified, the next step is to identify and obtain the replacement parts needed for the repair. Most turbines use standard parts, but in some cases, custom parts may be required. In addition, it is important to select parts that are compatible with the turbine and its operating environment.

Repair Techniques

The techniques used for steam turbine blades repair depends on the type of damage and the material of the blades. Common techniques include welding, brazing, machining, and grinding. In some cases, the blades may need to be replaced entirely.

Once the cause of the damage is identified, the blades can be repaired. One of the most common repair methods is to weld new material onto the blade. This is done by a trained technician, who uses specialized tools and techniques to ensure the weld is strong and secure. Other repair methods include machining, grinding, and brazing. These techniques are used to remove any damaged or worn material and replace it with new material.

Assembly and Testing

After the repair is complete, the blades must be reassembled and tested. This process typically involves inspecting the blades for any signs of damage or wear and ensuring that the parts fit correctly and function properly. If any issues are found, the blades may need to be repaired again or replaced.

Maintenance

Regular maintenance of steam turbine blades is important to ensure long-term performance and reliability. This includes regular inspections and repairs, as well as preventive maintenance such as lubrication, cleaning, and balancing. Regular maintenance will help to extend the life of the turbine blades and keep the turbine running efficiently. In conclusion, steam turbine blade repair is a complex process that requires specialized knowledge and equipment. By understanding the basics of turbine blades repair and performing preventive maintenance, technicians can ensure that the turbines continue to operate safely and efficiently.

Conclusion

Repairing and replacing steam turbine blades is a complex process that requires specialized tools and knowledge. The first step is to inspect and diagnose the cause of the damage, then the blades can be repaired or replaced. Welding, machining, grinding, and brazing are all common repair methods, while blade replacement is used for severe damage. Professional technicians are essential for ensuring the best possible repairs and results.